In the industrial business, mill vs lathe machines is two crucial devices. Both entail using cutting techniques to cut material from a workpiece in the form of a swarf (chips), but they’re not the same. The tasks and purposes of both lathes and milling machines are distinct. So, exactly precisely is the difference between these two machines?

In mill vs lathe: What Is a Lathe and How Does It Work?

A turner is a massive project that looks like a regular workstation. It rotates a product against such a single-bladed cutting tool and is made up of roughly a dozen separate elements, including a bed, carriage, headstock, tailstock, faceplate, and so on.

After mounting the workpiece on the lathe, it is turned against a single-bladed cutting tool. To help remove, the workpiece stays fixed while the workpiece spins against it.

Based on the conditions that, lathe and milling machines, are used to extract, lathes are classified as either woodworking or metalworking like Grizzly G8688 and Jet 1440 Lathe.

Woodcraft lathes are shorter and have smaller samples than metallurgy lathes, but they also depend on the attached workpiece’s rotating ability to eliminate material when it is exposed to a singular cutting tool with milling lathes.

Mill vs lathe: What Is a Milling Machine and How Does It Work?

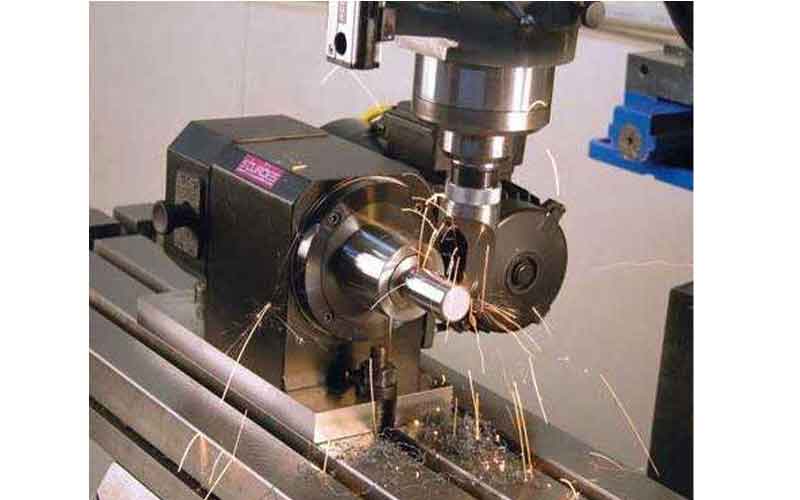

A milling machine is a machine that removes material from a workpiece by feeding it against a cutting tool with several blades or points. Milling machines are higher than lathes, but they’re also shorter, enabling manufacturers to fit them into tighter places.

Apart from than shape and function of lathes and milling machines, the main distinction between lathes and milling machines is the way they work on lathe vs mill. The workpiece revolves on a lathe against a fixed cutting tool. A stationary workpiece like a lathe vs milling machine is subjected to a spinning cutting tool in machining processes.

In particular, the milling machine’s cutting tool generally contains many knives or edges. The cutting tool used in lathes, on the other hand, normally has just one blade. milling on a lathe machine may remove material from a workpiece by using several blades or tips.

Face milling and periphery milling are two types of milling operations. A cut activity around the exterior of the cutting tool is known as face milling, while a cut activity throughout the circle of the cutting tool is known as peripheral milling.

To extract material from the workpiece, both lathes and machine tools are utilized. Milling machines, on the other hand, include revolving a multi-bladed or -pointed cutter against such a stationary workpiece, while lathes include spinning a single-bladed cutting tool against a stationary workpiece.

Mill vs lathe Machines: difference between milling and drilling

Milling and lathe equipment is found in most contemporary production facilities. Each machine works on the same compositional machining technique, which involves starting with a block of material and shaping it to the outcome expectancy.

The fundamental difference between the two machines is how the component is actually formed. Explaining the relationships in more detail will aid in the placement of the correct component in the correct machine to optimize their potential.

Even with some midi lathes, you will need a milling machine for your particular purposes. Let’s find out some best midi lathes for your work.

The operation is underway.

The interaction between the workpiece and the tool is the most significant distinction between a milling machine and a lathe machine i.e lathe vs mill.

Machines for turning.

The workpiece being machined rotates around its axis in a lathe, while the cutting tool does not. This is known as “turning,” and it’s a good way to make cylindrical pieces.

Drilling, boring, threading, ID and OD grooving, and parting are all common operations performed on a lathe. The lathe machine is the greatest option for making rapid, repeatable, and symmetrical cylindrical pieces.

Machines for milling.

Milling machines, on the other hand, are the exact opposite. In a milling process, the tool revolves around its axis, but the workpiece does not. This enables the tool to approach the workpiece in a variety of orientations, which is necessary for more elaborate and sophisticated pieces. If you can program it, you can mill everything as soon as you have the right clearances and tools.

Optimal Procedure

The adaptability of a milling machine is the greatest incentive to employ one for a future project. There are hundreds of specialty cutting tools and numerous designs of end mills available for milling machines, ensuring that you are covered from start to finish on any task.

A mill, unlike a lathe like Bolton, can cut more intricate components. On a lathe, for instance, it would be difficult to make an intake manifold for an engine effectively. A milling machine would be necessary for the effective machining of such complicated pieces.

When it comes to mill vs lathe, Lathe machines have fewer applications than milling machines, although they are better for cylindrical items. While a mill can produce the same cuts as a lathe, creating the very same product may need many setups. A lathe will outperform a mill if constant manufacturing of cylindrical components is required, increasing both performance and efficiency.

What is the difference between a mill vs lathe?

Lathes and milling tools are the ideal workplace brothers: they have a common interest in molding and cutting, but they never cross paths.

What is the difference between mill and lathe?

The approach used by these two devices is the most significant distinction between them. Lathes rotate whatever substance you’re dealing with while keeping the workpieces stationary. The cutter blades of a milling machine spin whereas the material stays still.

However, if you are looking for some beginner wood lathe, then you can take a look at these.

Lathes in action.

To put it another way, the lathe rotates as you shape. This shaping is done with your fingers and power tools in ceramic; it is performed with focused addition of pressure in glass blown, and it is performed with the lathe’s chuck jaws spinning the materials while an insertion cutter molds and outlines it in metal and woodwork.

WORKING MILLING MACHINES

Milling machines, with exception of lathes, use rotating cutters to form the substance between each quick pass. The milling machine market is rather diverse, with a variety of machine types, arbor rotations, and blades to choose from, depending on the work at hand. CNC (Computer Numerically Controlled (CNC) CNC lathe and milling machine devices that automate the milling process are now available.

What is the difference between a lathe and a milling machine?

It’s a lathe.

Turning, facing, drilling, cutting, sanding, deforming, and knurling are all skills that the lathe excels at.

The machine’s versatility allows it to be used for a variety of tasks, including:

• Bats for baseball.

• Vases and bowls

• Cues for the pool table.

• Instruments made of wood.

• Camshafts are a kind of camshaft.

• Barrels for firearms.

• Threads on bolts.

• Metal surfaces with patterns.

• Pottery is a kind of art.

• Glass that has been blown.

The form of the material you can work with is where it is constrained. In most cases, you’ll start with cylindrical material and shape it using a lathe.

MACHINE FOR MILLING.

Drilling, boring, cutting, shaping, flattening, and round-off corners are all skills that milling machines excel at. They provide you with additional options when it comes to material selection.

The milling machine, such as the lathe, is a jack of all crafts, and its work may be seen in:

• Metal sculptures and engravings.

• Trophies are a kind of award.

• Automobile components (new or repaired).

• Fixtures used in construction.

• Gears are a kind of machine.

Interesting information.

The 3D printer was created as a mirror image of the milling machine. Machining products operate in a parametric method, eliminating materials to produce the final output. The 3D printer uses additive technology to create items out of tiny layers of powder, rather than out of thin air.

The mill and the lathe are compared analytically.

Milling and lathe machines are found in large numbers in production facilities since both have important roles to play in production and assembly line operations.

Both milling and lathe machines employ the same subtractive machining concept, in which a block of material is utilized to get the required shapes and specifications. The mechanism by which the form is obtained is the distinction between these two machines mill vs lathe.

The substance being used rotates on its spindle in a lathe machine, whereas the cutter stays stationary. This is known as ‘turning,’ and it is a good way to make cylindrical pieces. As a result, the lathe machine is the best option for producing rapid, repeatable, and symmetric cylindrical components.

Milling machines, on the other hand, have a totally different mechanism, in which the tool spins on its axis while the workpiece remains stationary. Because of the milling machine’s different orientations, it’s possible to do a variety of delicate and complex operations.

A most advantageous feature of a mill lathe machine is its adaptability since the operations that may be performed with it are almost limitless. Milling machines come in a variety of cutting tools and types to serve an overwhelming amount of purposes.

Machines (Milling) are being used to create more complex designs, such as an air intake, that would be impossible to do using a lathe.

Although the milling machine can create more complicated and complicated designs, the lathe machine outperforms the milling machine when it comes to cylindrical components, as well as the lathe appears as the best equipment when a constant production of factors represent is necessary for mill vs lathe.

The Distinction between Working Methods of mill vs lathe

Both machines may be distinguished by their functioning methods, which are diametrically opposed.

These cutters of a lathe machine remain motionless while the wooden or metal piece is turned to create different forms. The product is held in the chuck on the headstock, which spins continually, and the cutting tool is held in the tool holder, which is tightly secured so that it cannot move.

5 Best Lathe Mill Combos

Can you do milling with a lathe? Well, in this part we will show you some ways for milling with a lathe with the combos.

Grizzly Industrial G4003G – 12″ x 36″ Gunsmithing Lathe with Stand

We fitted a 3/4 HP motor precise gear head mill to our immensely renowned G4003G Gunsmith’s Lathe to create the ultimate “small footprint” metalworking station for both machinists and gunsmiths.

But don’t be fooled by its little size; this lathe mill combination has really large machine capabilities including an R-8 mill spindle and a D1-5 lathe spindle.

Perhaps it offers a comprehensive set of task-holding and tool-holding equipment and tools to get you started drilling, turning, milling, boring, chambering, and facing like a pro!

Characteristics

Its tailstock on the lathe mill is 1/2 sq drive, which may be used with the torque wrench to consistently lock the tailstock down. It uses LED work lights and is energy-efficient. Aside from it, the lathe includes an expanded cast-iron base platform and a carriage switch on/off.

The Grizzly Industrial Combination Gunsmithing Lathe’s roller bearings are smooth and follow the rest of the machine. It also aids in thread cutting on both the LH and RH sides.

The lathe comes with a splash shield and chip tray, as well as a 9-3/4″ x 5-7/8″ table with T-slots.

7-1/4-inch-wide bed “40mm spindles bore MT#5 Spindle Nose Taper D1-5 Spinning nose Camlock is a fictional character. 6-1/4″ cross slide travel, 3-1/4″ compound slide travel MT#3 tailstock barrel taper 4 travel of the tailstock barrel” 9 different speeds 70, 200, 220, 270, 360, 600, 800, 1000, 1400 RPM are the speeds available. Height without stand: 23″ Height with stand: 54-1/2″ Length with stand: 61″ Width of stand: 26″ Height without stand: 23″ Height with stand: 54-1/2″ The shipping weight is estimated to be 1374 lbs.

One of the clients said,

It’s been approximately a month since I received my new G4003G lathes milling. I’m quite happy. The level of vibration is really low. (I bolted the base to the floor of my garage.) Minor gripes: Grizzly should have included an oil drain valve on the headstock to allow for oil drainage. The plug given was really clumsy.

The next time I change the oil, I’ll install a little valve of the milling machine lathe. The shipping containers were in good condition, albeit there was some paint scratching. I received some touch-up paint from Grizzly. The tailstock quill travels 4″, however, because of the extraction mechanism, you only receive around 21/2″ of drill excursion. Overall, I would really suggest it.

Hengwei Desktop Mini Lathe Drilling And Milling Machine 180W Mini Lathe Clock Machine To Teach Machine 220V

One of the greatest lathe mill combinations is the Hengwei Desktop Mini Lathe Drilling And Milling combination lathe mill drill, which comes with a two-year guarantee. With this best-designed lathe mill combination drill, the user may also enjoy a 90-day in-shop trial.

Companies also deliver the user instruction on how to operate the equipment and get them a free set of tools when they buy it. Smithy Tools are used to create and repair components in a wide range of applications.

The owners of the Hengwei Desktop Mini Lathe Drilling And Milling lathe mill combination are likely to make money and save money once the equipment is operational.

Turning on a lathe

This lathe spins the sizes to exact specifications on the exterior and interior. With a cut inch and metric thread, it performs taper twisting and faces cuts. The turning mill can cut metal as hard as carbon steel, as well as soft materials like plastic and wood.

Drilling is the process of drilling holes in the ground.

The driller’s head revolves completely 360 degrees, allowing it to handle a huge workpiece. In about the same project, the mill and drill may be utilized interchangeably. The driller has three distinct sorts of heads: counterbore, tap screw and countersink. You can also buy used lathes and milling machines in the store where they sell old stuff. However, buying a new one always keeps up the thrill.

Milling is the process of grinding grains.

This milling machine lathe could flatten curves, edges, and niches with precision when using the mill. It makes slots, recesses, angles, and aligns the surface of the metal with accuracy. With the correct speed, the mill may also create slots and grooves.

220V 180W Multi-function Mini Lathe Machine Desktop DIY Drilling Milling Machine

With three 140W T-nuts, the Multi-function Mini Lathe Machine fits comfortably in the 150 x 110 mm supplied PD 400 lathe-slotted table. The motor rotates at a rate of 280 to 2,200 rpm. It can also turn the PD 400 lathe mill combination into complete machining equipment.

This robust condensing device can rotate in both CW and CCW directions, and that is beneficial while cutting threads of the milling lathe machine. A machined table measuring 150 x 110 mm with a T-slot completes the lathe. It is made up of 45 x 500 columns.

Aside from that, the Proxxon lathe milling machine offers diameters 6, 8, 10, and 12 mm, as well as a fitting flange. This precise micro lathe can handle a wide range of tasks. That device can conduct counterface turning, drilling, threading, and cutting on materials composed of round bar and bar components.

Proxxon 34104 Mill/ Drill Head PF 230, 1.38 X 15.75-Inches

Proxxon 34104 Lathe Mill Combo is built with high-quality equipment that runs on 110-120 V, 140W, with speeds of 280, 550, 870, 1,200, 1,500, and 2,200 rpm.

Along with X-Y movement, which would be transverse and cross-sectional, the lathe mill combination functions as a smooth surface. This milling lathe machine comes with three sets in the sizes of 25/64″, 15/64-5/16″, and 15/64-5/16″. (6, 8, 10 mm).

The PF 230 Mill/Drill Head transforms your PD 250/E Lathe into a machining center. The Mill/Drill Head PF 230 comes with a 1 3/8″ x 15 3/4″ (35 x 400mm) column, as well as the appropriate circuit board and bolts for use with the PD 250/E Lathe.

The table (provided with the Mill/Drill Head PF 230) is then used to substitute the upper slider on the lathe. The table is 4 5/16 inches in diameter “15/32″ x 15/64″ x 15/64″ and 3-T slots 15/32″ x 15/64″ x 15/64” (12 x 6 x 6mm). This lathe also serves as a compound table, having longitudinal and cross-wise X-Y movement, respectively.

Sizes 15/64″ – 5/16″ and 25/64″ are available in three collets “6mm, 8mm, and 10mm are supplied. 280 – 550 – 870 – 1,200 – 1,500 and 2,200rpm, 110 – 120V, 60Hz, 140W (0.1877hp), 110 – 120V, 60Hz, 140W (0.1877hp). Note that the lathe is not included.

This lathe milling machine table (provided with the mill/drill head PF230) is then used to replace the top slide on the lathe. The table is 4-5/16-Inch by 2-3/4-Inch (110 by 700mm) and has three T-slots measuring 15/32-Inch by 15/64-Inch x 15/64-Inch (12 by 6 by 6mm).

This lathe now serves as a composite table, having transverse and cross-wise X-Y movement, correspondingly. There are 3/4 of carbide inserts that include: 15/64-inch, 5/16-inch, and 25/64-inch.

Shop Fox M1018 Combo Lathe/Mill

This flexible device is not to be missed by hobby or enrollment machinists. This combination lathe has a 4-way turret tool post, 9-1/2-inch faceplate, 4-inch 3-jaw chuck, and a built-in rotating vise, making it ideal for turning, cutting threading, drilling, and milling small tasks. The swing over the bed is 16-1/2 inches, the swing over the saddle is 11-1/2 inches, and the length in between centers is 19-3/16 inches.

In the very same way that the energy feed moves the carriages all along the main shaft, the transverse thumb crank enables you to manually move the carriage along the lead screw. Because when the cutting tool meets the material, the graduation dial on the cordless screwdriver shaft travels autonomously of the hand crank and maybe ‘zeroed,’ enabling you to maintain track of the tool’s position and motion.

Hand-wheel for manual cross-slide.

A mechanical cross slide wrist with graded dial and a complex slide that can be changed to any degree and travel smoothly along that angle are also included in the M1018.

Tool Post for the Turret.

The Model M1018 comes with a barrel tool post. Up to four 12-inch instruments may be stored on this tool post. With enabling you to easily release the lock lever and move toward the next tool, having many tools mounted in the cutting tool saves time.

The tool post has a spring-loaded catch that allows you to spin the turrets 90 ° at a moment. With shutting down the levers, the tool post may be properly secured at any rotating position.

Last but not least,

Being a good craftsman, you’ll need a decent device like mill vs lathe to help you pave the way. Buying a device that meets your requirements is likewise a crucial effort.

Many individuals are unaware of the small but significant distinctions that exist between a lathe and a milling machine.

We’ve attempted to detail all of the relevant distinctions between mill vs lathe because that you can tell them apart more easily. I hope this information is useful to you.

If you still have questions, you may use the comment box below.

On the other side, I’ll see you. Well, not on the opposite side, but in a different thread. Just joking!